Key Facts

Project Synopsis

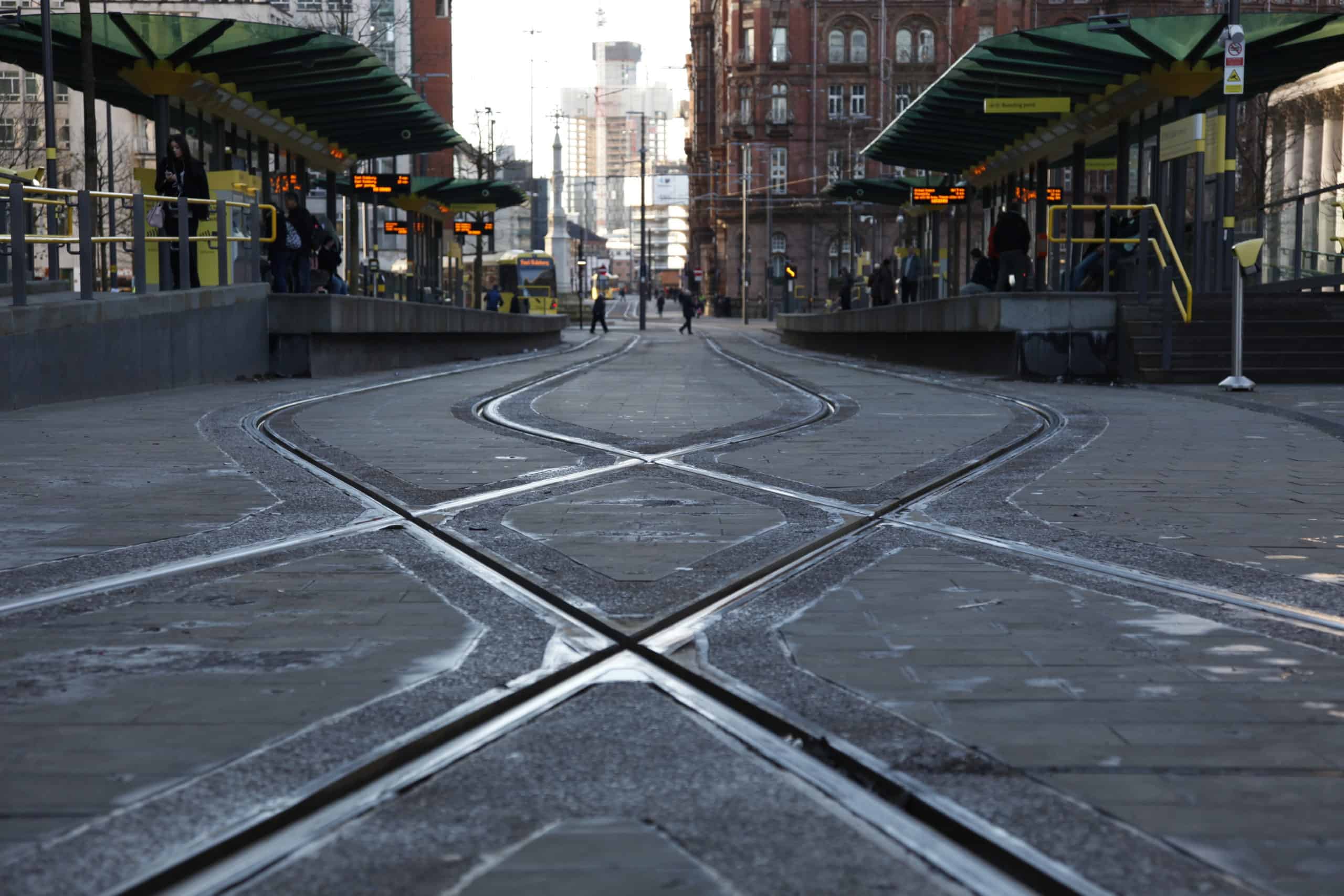

KeolisAmey Metrolink, a joint venture between Keolis and Amey, took over operations and maintenance of Manchester’s Metrolink up to 2027. The network consists of 93 stops, seven different lines along almost 100km of track, with a fleet of 120 modern trams catering for more than 34 million journeys a year.

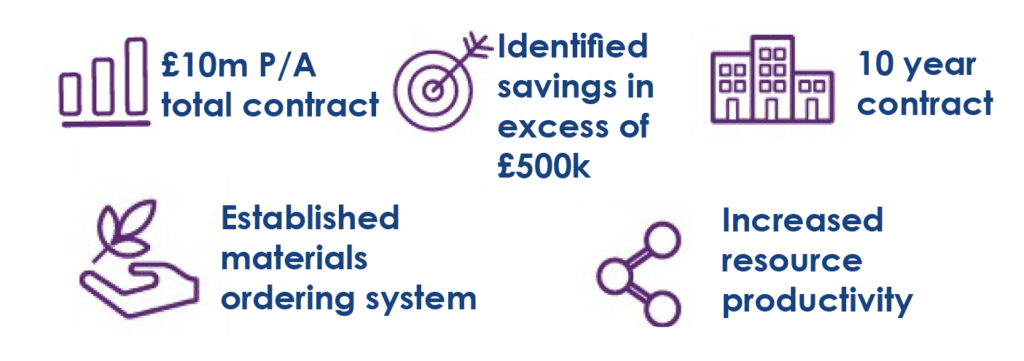

TSS reviewed and identified opportunities in the £10 million spend per annum (exc. power supply) across a variety of products and services inclusive of track, OHLE through to nuts and bolts.

Whilst the network is well serviced, the commercial mechanisms need to be reviewed to ensure that best value is being delivered in the short, medium and long term.

Scope of Works

- Contract administration of supply chain in line with terms and conditions.

- Working to good industry practices e.g. minimum Construction Act requirements.

- Commercial management of accounts for high spend companies.

- Formulate and introduce formal process DOA authorisation prior to starting works.

- Build detailed assessment spend executed to provide high level re-bid / benchmark information.

- Review overtime process and understand requirements vs outputs.

- Re-procure heavy engineering material supply agreements.

Overcoming Challenges

Working within the light rail industry in a 24/7 environment where works are executed out of hours can provide challenges when establishing when and where works have been carried out. To identify which vegetation had been managed and drains jetted trackside we geo-located every OLHE station with longs and lats data. The information returned from site within the mobile app could then be overlaid to not only substantiate the location but also identify

hot-spots.

Successes

During our engagement we identified substantial savings across various non-construction cost heads such as security provision for Special Events, Rail Replacement Buses, and De-Vegetation of in excess of £500k. The additional commercial governance introduced by TSS has also provided a long-term platform for future improvements to be built from.

Testimonial

TSS came into a fast moving environment and quickly identified areas of opportunity not only in terms of cost saving through commerciality but also through process efficiency and improved governance. Working within the business they formed an integral part of the team with skills enabling them to interface with all contract stakeholder successfully

James Burgess

Head of Rolling Stock & Supply Chain